Calculator Types Calculator blog

Calculator blog

Musings and comments about our common interest

The innards of the new HP15c CE

Hi,

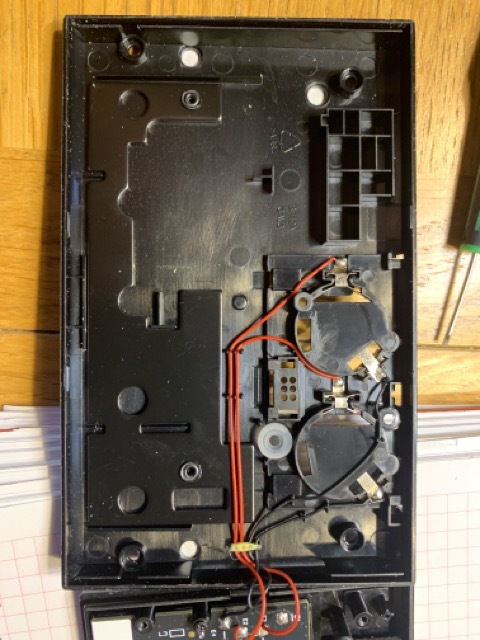

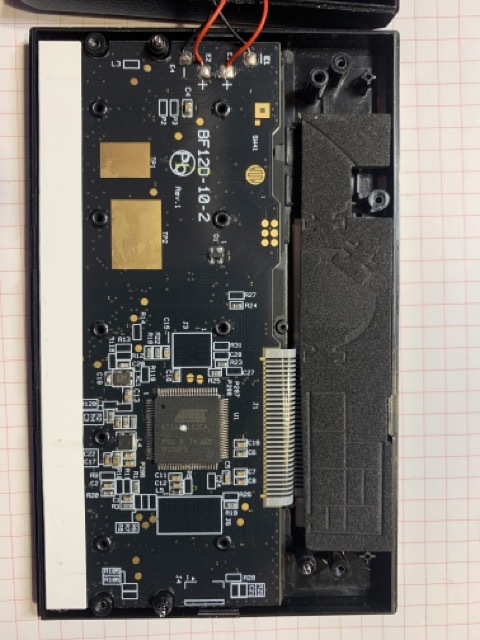

I tried to work on the keyboard of a HP15c CE. I opened it, taking out the 5 screws (do not forget the one beside the battery!). Here is what can be seen inside:

If you are DIY inclined, you could add a standard nano-USB on the left side of the calculator (which is on the right side in the picture). Beware: it requires drilling your precious unit!

On the other hand, no way to go into the keyboard: many permanente fixings, risking to break the calculator.

Continuation of "New glue..."

I have been using the Schwanheimer Industriekleber 100 glue already for some time. When properly using (making generous use of the primer on both sides) it is the best glue I have used for calculator repair. Better and thinner than E6000; no comparison with E6000+; and miles ahead than other cyanoacrylates. I think the primer makes all the difference.

You can read my initial feelings on this glue here: http://www.thecalculatorstore.com/Calculator-blog/A-new-glue-for-HP-repairs

So much so that when the glue is finished (the primer is not, yet), I have gone to their website and bought the whole pack: it comes in a portable plastic bag. I am looking forward to finish all the repairs that I have in front of me, and I will report later. It includes an accelerator, a filler, a mechanizable patty and a solvent too.

Next developments for the HP15c CE

The enhancements I foresee for the HP15c have to do with the cable and firmware posibilities:

- Backup and restore user memory

- Some kind of memory manipulation of the user memory file, so that it can be used in other software like Thorsten Manz's fantastic HP15c.

Both things together can create an ecosystem for the HP15c. So far, entering a program was cumbersone and had to be done each time. With backup and resotre, + memory editing outside of the calculator, you will be able to exchange software between users - and development and use will skyrocket compared with having to enter any single program yourself.

Let's see. I have heard that there are already firmware prototypes to do that.

Cable VI - what you can do with it!

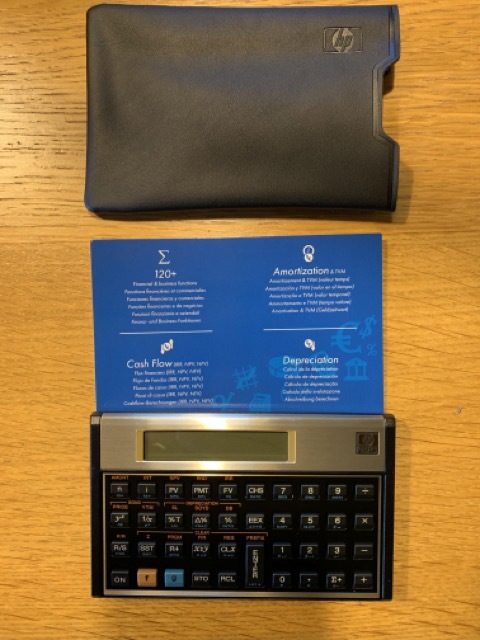

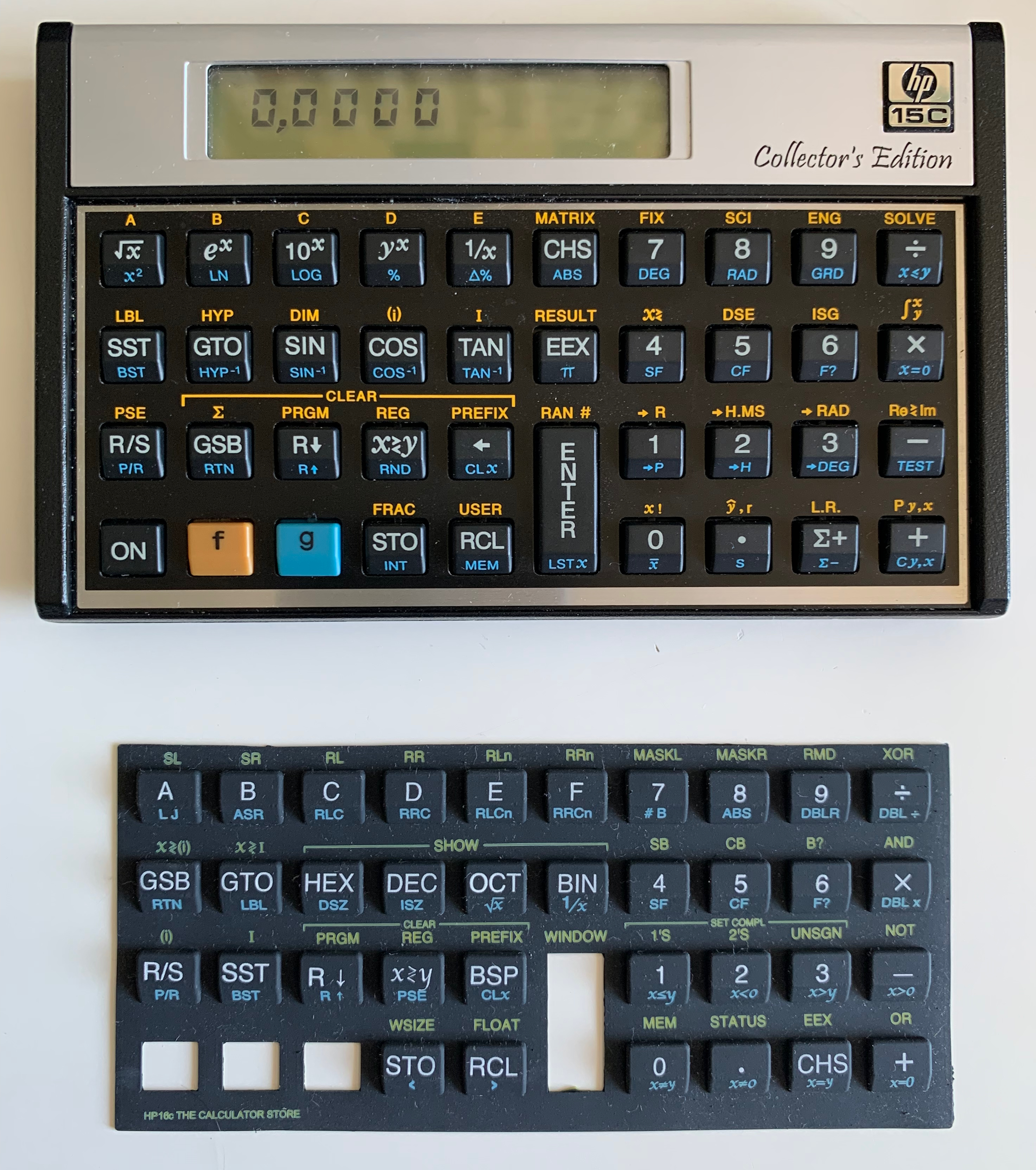

I have already had 3 customers that have purchased a HP12c (NOT HP15c CE !!) + the programming cable + HP16c overlay.

I have already had 3 customers that have purchased a HP12c (NOT HP15c CE !!) + the programming cable + HP16c overlay.

You can guess what the plan is: to get a much cheaper HP16c in addition to their HP15c CE (which all three purchased before, with the newest firmware already fixing the DEC bug in HP16c.

Also, around 300 customers have purchased the cable to fix their firmware. While this is the original reason, these customers will profit of the cable in ways that we can only imagine. So far, when you rewrite the calculator firmware, you need to reset it and all programs and data previously introduced are lost.

However, the Atmel processor has other USB modes that can be used to back up the user memory, and restore it if needed. This opens the possibility for multiple configurations, and even HP15c "application pacs"

Cable V

Finally we received the cables (just 300 units of the 1000 ordered- the rest after Chinese new year), and we are shipping them to customers already. Hold on- yours is about to be sent if it hasn't yet.

On the other hand, we have created some pages with information on the use of the cable. We have just focused on the current use, but there will be more! So I would also consider obtaining a 3D printed back door - to avoid having to carry a screwdriver with you!

cable V !!

We finally have a DHL delivery date for the cables ! We are receiving them this Thursday. We have already prepared many packages and documents to be able to send as many as we can immediately.

The cables have CE certification. I will post it here when I get the original copies of it.

cable IV

Here are some pictures of the complete cable:

Hopefully sent to customers by the end of the week.

There will be some sort of compensation for the delay to all.

Battery door for the back door hp19bII

The HP19bII is a fantastic calculator with one of the most complete function sets. It was the workhorse of the MBA I did at the beginning of the nineties. Most of my companions were using this calculator.

The HP19bII is a fantastic calculator with one of the most complete function sets. It was the workhorse of the MBA I did at the beginning of the nineties. Most of my companions were using this calculator.

However, several years later most units had been damaged at the same point: the side door. Nearly all units after a long time become brittle and break over time.

Hewlett-Packard recognized this problem and redesigned the calculator, moving the battery door to the back. There were other minor changes, with a darker brown body and black keys instead of the grey of the past version. This model is much more demanded nowadays - because it lasts.

I bought one in a local second hand site, but it was missing the back door. So I designed one for it. I thought that there would be exactly one unit produced ever - this was not a piece that breaks, and it was difficult to lose too. So color me surprised when a customer asked me where such back door could be found. "It is here", I said.

So I take the opportunity to offer it to you all. However, I still think that there will not be a lot of orders - rationale is the same as it was when I designed it.

Cable III

Here is a picture of the complete cable:

Possible improvements to HP15c firmware

What could be improved on the HP15c CE by changing the firmware?

What could be improved on the HP15c CE by changing the firmware?

- Back up: in my opinion, the ability to write down user memory (including memory disposition) would be fantastic. not only you save your hard-entered programs, but you could store different profiles (EE, algebra, finance, others...) and change them "on the fly"

- Memory is now far less important - we have enough! there are some methods to bring it to 224 registers, but what's the point?

- Debouncing time adjustment - a little like screen contrast?

- Any other that you can imagine?